Control Systems Development

Designing, Programming, and Testing Product Behavior at Every Project Stage

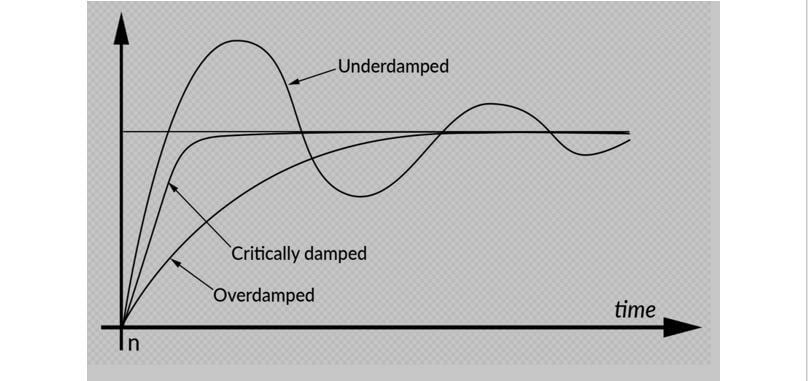

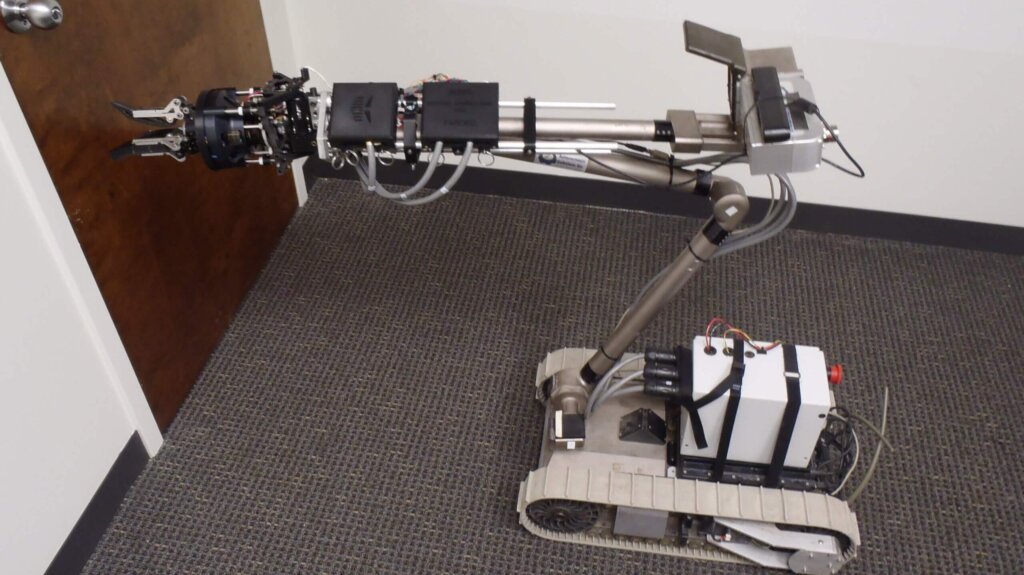

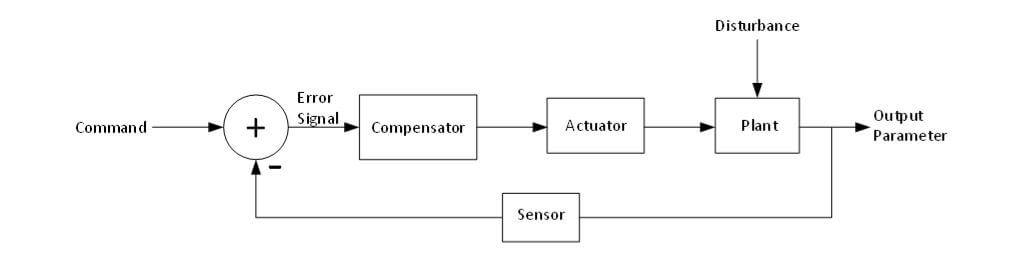

Boston Engineering is a leader in the development of custom control systems. Our integrated, cross functional team of electrical, software, and mechanical engineers will advise, direct, and manage any control system development project. Whether the challenge is to design a new control, increase reliability, improve performance, or synchronize responses, Boston Engineering thrives on solving the toughest challenges. From initial design consulting to turnkey product delivery, Boston Engineering experts support all phases of the Control System development cycle.

Gather Requirements:

Gather Requirements: