Boston Engineering shares insights into commercialization

The speakers at RoboSource represented a robotics integrator, a startup, and a component supplier.

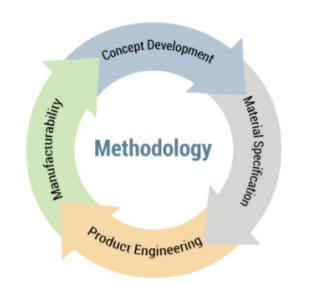

Mark Smithers, chief technology officer at Boston Engineering Corp., explained that his company provides services to help companies commercialize their technologies. Waltham, Mass.-based Boston Engineeering has centers of excellence around robotics, embedded systems, digital solutions such as augmented reality (AR), controls, and “DFX” or design for manufacturing.

With more than 25 years of experience in working with innovators and federal Small Business Innovation Research (SBIR) grants, Boston Engineering has focused on overcoming hurdles to commercial viability, said Smithers. He outlined challenges at each of the following stages:

- Research: Technology may not be ready, and there are plenty of opportunities to fail, Smithers said. However, it’s OK to fail early, as long as risk is managed. “Researchers and entrepreneurs will push the limits of technology,” he said.

- Feasibility prototype: Sometimes, a technology is not convincing, which is why Boston Engineering focuses on DFX in taking products from “presentable” prototypes at Technology Readiness Level (TRL) 6 to commercialization at TRL 9.

- Alpha development: A common mistake is not understanding the users’ needs, Smithers noted. It’s important to think about them and ask during the design phase, he said.

- Beta development: Startups need resources to scale, and not just money, said Smithers. Organizations such as MassRobotics can help, he said.

- Production: Bringing an innovation into reality requires overcoming uncertainty. “Big business will pull when a technology is believable and commercially viable,” Smithers said. He also emphasized the importance of knowing desired production volumes and retaining control of one’s own manufacturing capabilities versus fully outsourcing them.

“You need people to help bridge the gaps between ideation and capitalization,” said Smithers. “Find subject-matter and DFX experts.”

Defining a product with potential customers early on can even lead to product redesign, he added. As with burning capital during design and development, robotics makers should have a sense of timing to steady-state production, Smithers said.

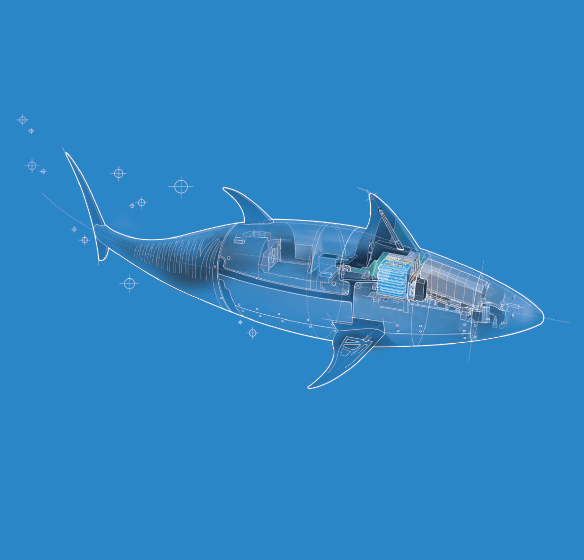

In addition, a modular design can help with future flexibility. Smithers cited the case of an underwater data-collection system that Boston Engineering developed for use by NOAA for hurricane forecasting, the U.S. Navy for mine countermeasures, and anti-submarine warfare.

Original Story written by Eugene Demaitre

Photo Credit: Eugene Demaitre

To read the complete article, click here.