Design for Manufacturability (DFM)

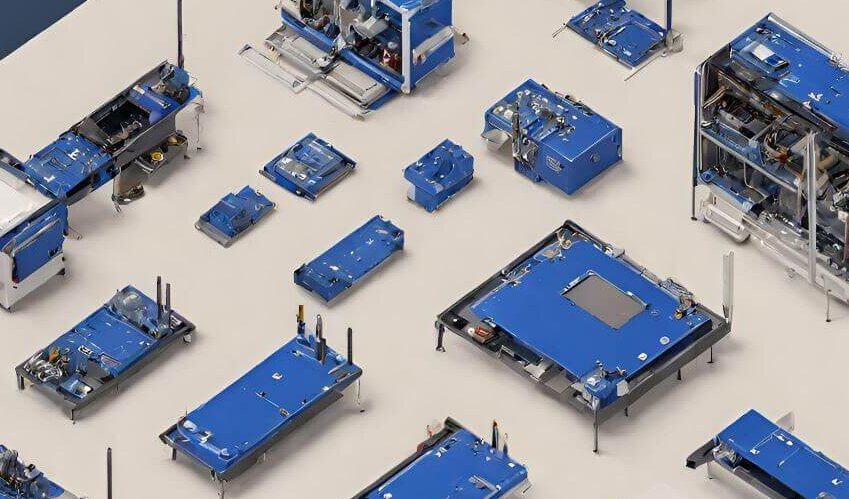

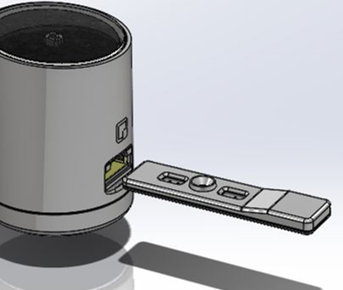

DFM focuses on optimizing the manufacturing process by designing components and products that can be reliably produced within cost, quality, and time constraints.

Our DFM approach includes:

- Simplifying designs for easier production with less process steps

- Utilizing common parts and materials when possible

- Designing parts for optimum manufacturability on available processes (injection molding, machining, etc.)

- Minimizing need for complex tooling and fixtures

- Eliminating secondary operations like drilling, tapping, etc. when feasible

- Considering capabilities of manufacturing partners early in the design process